Power to Heat

ÜSTA S/M: Die solare Übergabestation zur Schichtbeladung

ÜSTA L/XL: Die Pumpengruppen für große Solaranlagen

ÜSTA S/M: Die solare Übergabestation zur Schichtbeladung

ÜSTA L/XL: Die Pumpengruppen für große Solaranlagen

Thermally controlled apartment transfer stations for efficient 2-pipe networks in multi-family houses for mixed and unmixed heat distribution.

- FSU / FSM >>>

tuxhorn

offers you heating circuit groups from DN 20 to DN 40 with up to 12 m³/h or a maximum heating output of 250 kW, suitable heating circuit manifolds, hydraulic separators, magnetite separators, overflow valves and accessories.

Find out about our diverse offer.

Heating circuit groups versions

- PGR without mixer with lower pump shutoff

- PGM with 3-way mixing valve:

- 230V 3-point actuator

- 24 V, 0-10 V actuator,

- 230 V actuator with integrated constant temperature controller

- and with weather-guided heating controller

- PGM / PGR DN 25/32/40 VL right / left possible

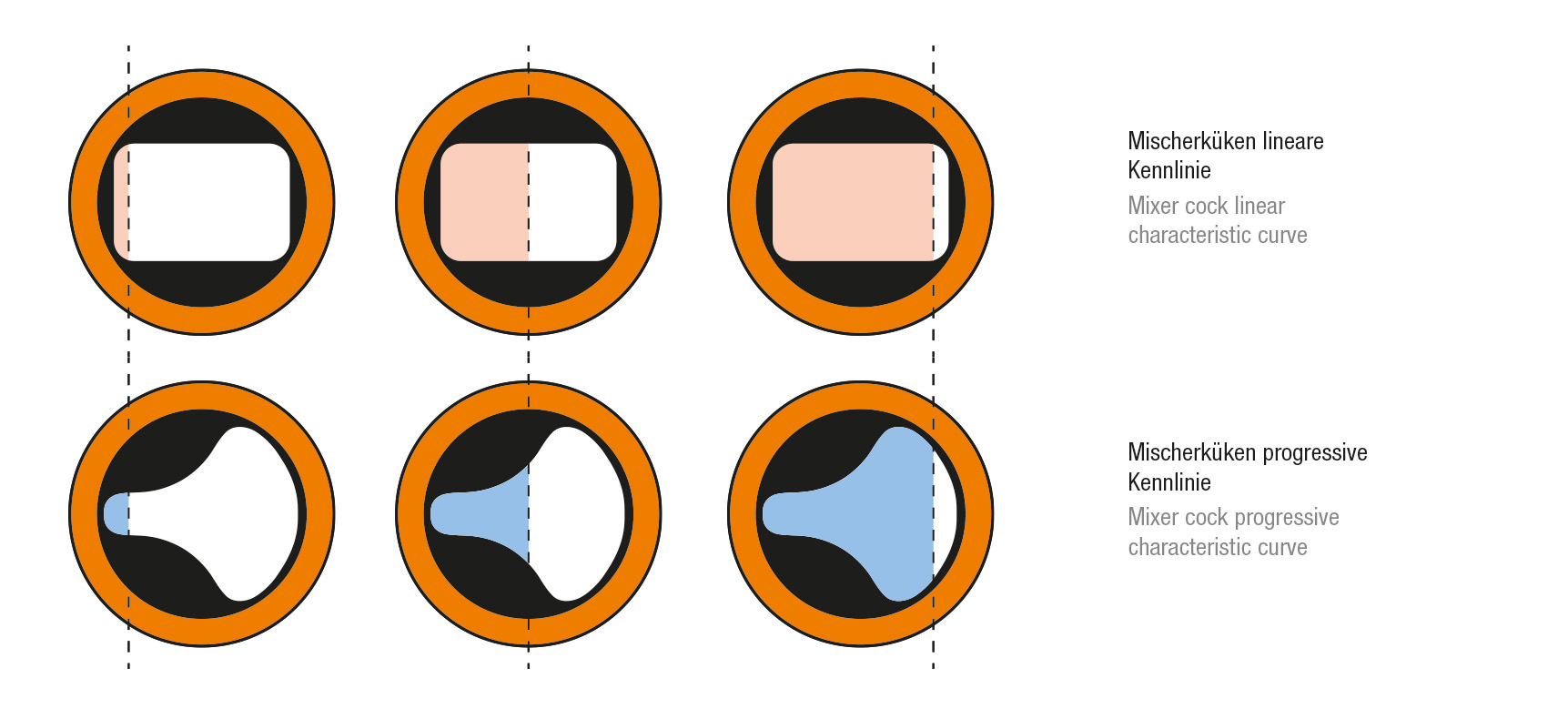

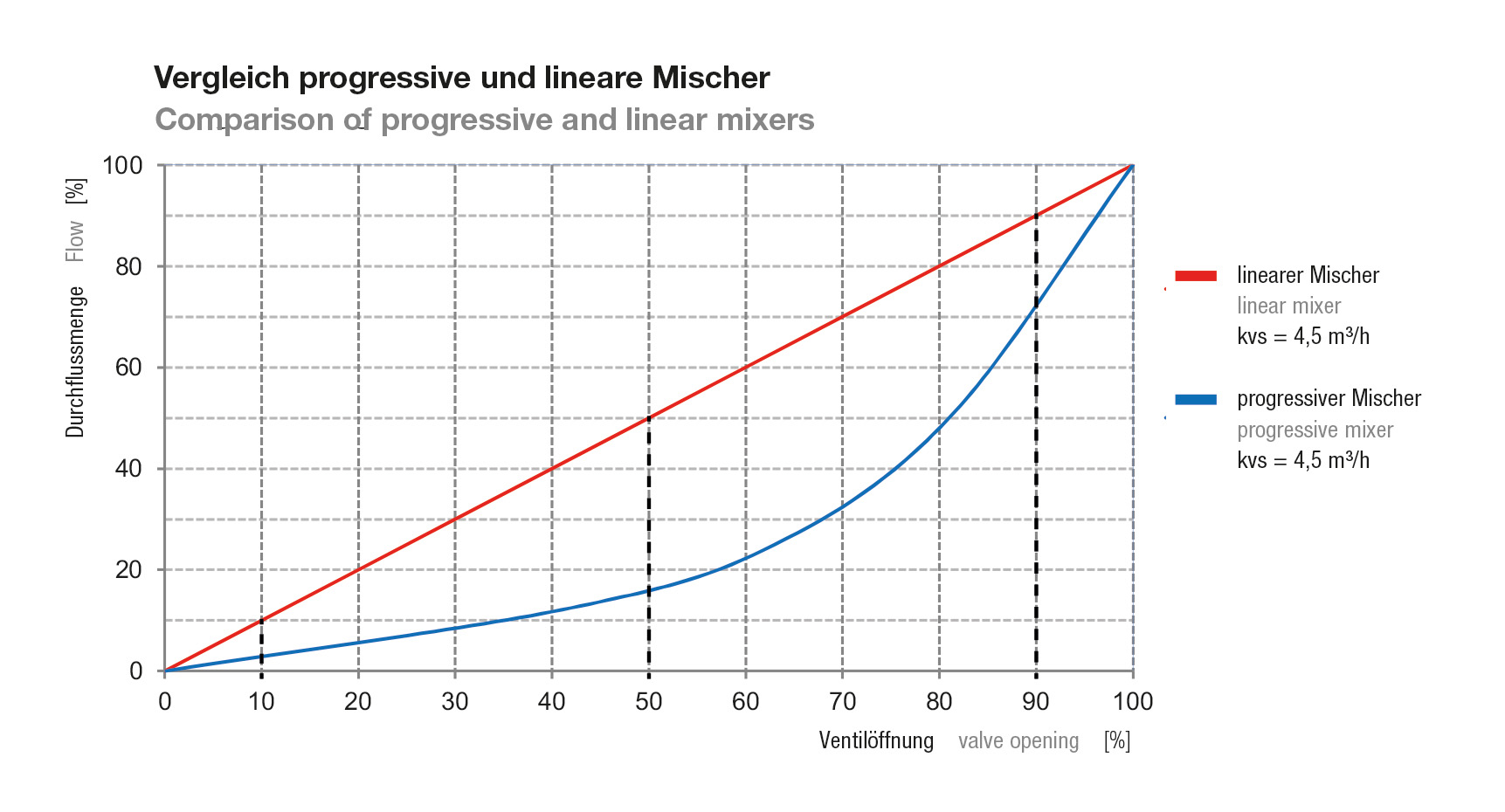

- progressive mixer characteristic with large kvs value

- ball valve spindles exchangeable from the front

- integrable magnetite separator tubra®-mag-jet

Characteristic curve tubra®-PGM

Control quality of the mixing valve:

The progressive characteristic of the rotary valve ensures that even with very low flow rates, the flow rate changes can be controlled very precisely over the entire 90° control range.

Resulting flow temperature:

The exact setting of the required volume flow results in a constant flow temperature. Thus, the building is supplied with exactly the amount of heat that is currently needed.

Product group Heating circuit

Heating circuit groups DN 20

tubra®-PGM/PGR S

The compact pump groups for mixed and unmixed heating circuits up to 45 kW heating capacity

Heating circuit groups DN 25/32

tubra®-PGM/PGR DN 25/32

The universal pump groups for mixed and unmixed heating circuits up to 90 kW heating capacity

Heating circuit groups DN 40

tubra®-PGM/PGR DN 40

The powerful pump groups for mixed and unmixed heating circuits up to 250 kW heating capacity